Thermoformed Products

Dedicated Customer Teams & Agile Services

Thermoformed Products

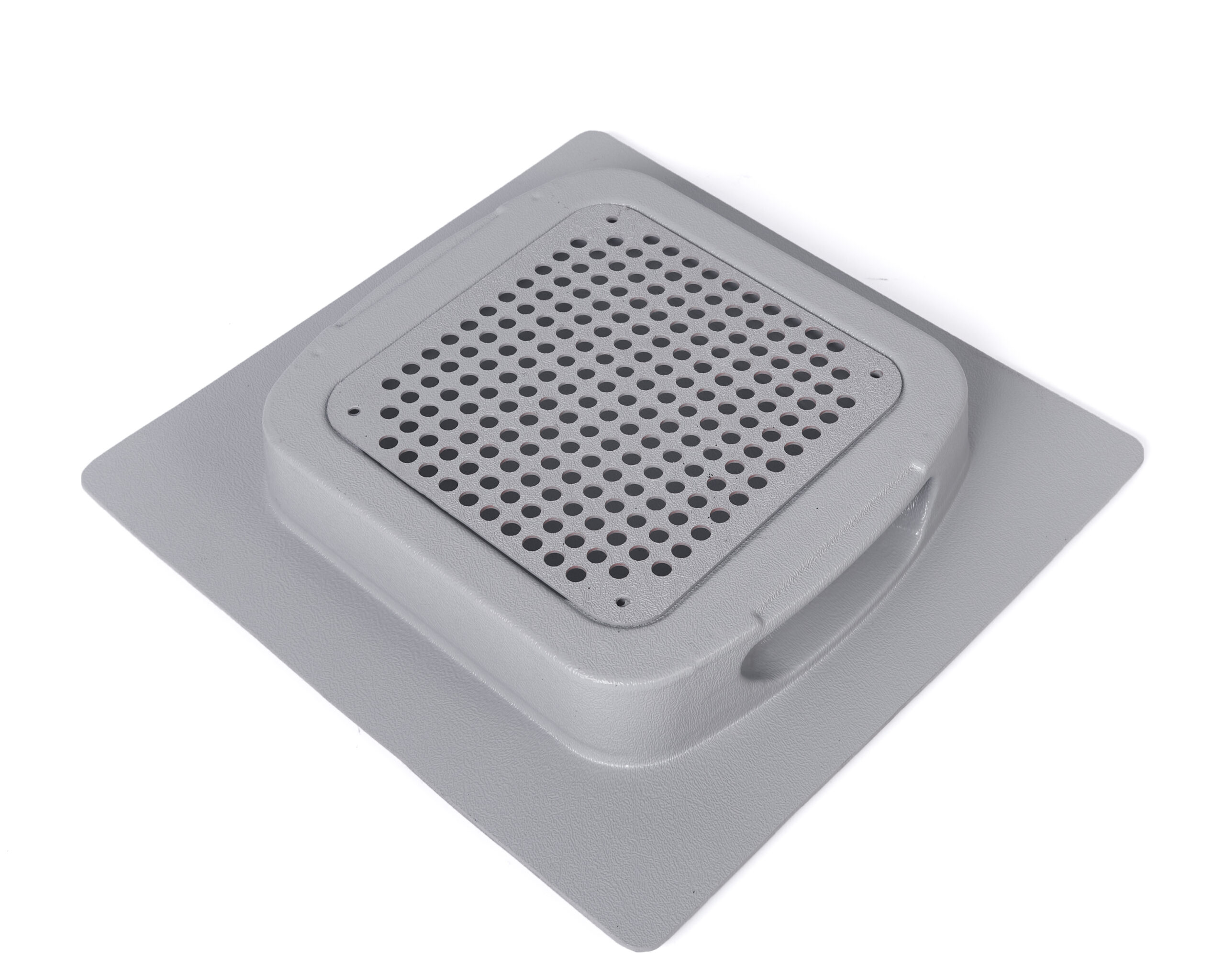

Thermoforming describes the process of heating a thermoplastic sheet to its softening point, stretching it over or into a single-sided mold, and holding it in place while it cools and solidifies into the desired shape. In Thermoformed products the thermoplastic sheet is clamped into a holding device and heated by an oven using either convection or radiant heat until it is softened. The sheet is then held horizontally over a mold and pressed into or stretched over the mold using vacuum pressure, air pressure, or mechanical force. The softened sheet conforms to the shape of the mold and is held in place until it cools. The excess material is then trimmed away and the formed part is released. Excess material can be reground, mixed with unused plastic, and reformed into thermoplastic sheets.

Single-Sheet Thermoforming

Thermoforming is a generic term for the manufacturing of plastic components through the vacuum or pressure forming processes. An overview of the single-sheet thermoforming process consists of heating extruded plastic sheet and forming the sheet over a male mold or into a female mold. Depending on what type of mold a customer selects, the thermoforming process allows the customer the ability to receive a part with the same aesthetic properties as an injection-molded part at a fraction of the tooling expense involved when you compare the cost in injection molding.

Twin-sheeting Thermoforming

There are many types of Thermoforming process is available. For example single sheet thermoforming, lug assisted, Pressure forming, Vaccumforming, twin sheet thermoforming. Twin-sheeting is heating two sheets of plastic and then forming and sealing the two sheets of plastic together during the forming process. Materials like PVC, ABS, PETG, ACRYLIC, PP, HDPE can be thermoformed up to 10 mm thickness.

Heavy gauge Thermoforming

Materials used in the Heavy gauge Thermoforming includes ACRYLIC, HDPE, LPPE, PP, PVC, PETG ,Polycarbonate. Our Heavy gauge Thermoforming expertise allows us to produce custom made plastic parts with an elegant look for Medical Devices, Outdoor equipment’s such as Car tire Inflator, Frame equipment tractor roofs, Golf cart roofs etc.…. Another advantage of Heavy gauge Thermoforming, is lower tooling cost and much lower minimum quantity runs. Economical low-volume runs are possible with thick gauge thermoforming as opposed to much more expensive upfront tooling cost of injection molding. All of this is achieved, while controlling the aesthetics and incorporating the colors and branding of our customers.

Military Shield Thermoforming

Materials used in the Heavy gauge Thermoforming includes ACRYLIC, HDPE, LPPE, PP, PVC, PETG ,Polycarbonate. Our Heavy gauge Thermoforming expertise allows us to produce custom made plastic parts with an elegant look for Medical Devices, Outdoor equipment’s such as Car tire Inflator, Frame equipment tractor roofs, Golf cart roofs etc.…. Another advantage of Heavy gauge Thermoforming, is lower tooling cost and much lower minimum quantity runs. Economical low-volume runs are possible with thick gauge thermoforming as opposed to much more expensive upfront tooling cost of injection molding. All of this is achieved, while controlling the aesthetics and incorporating the colors and branding of our customers.